Finest Lift Maintenance Company Options Near Me for Professional Lift Repairs

Wiki Article

Lift Maintenance Repair Elevator Suite Britannia Street Tividale B69 2PG 01926 266127

Necessary Variables to Consider for Elevator Maintenance

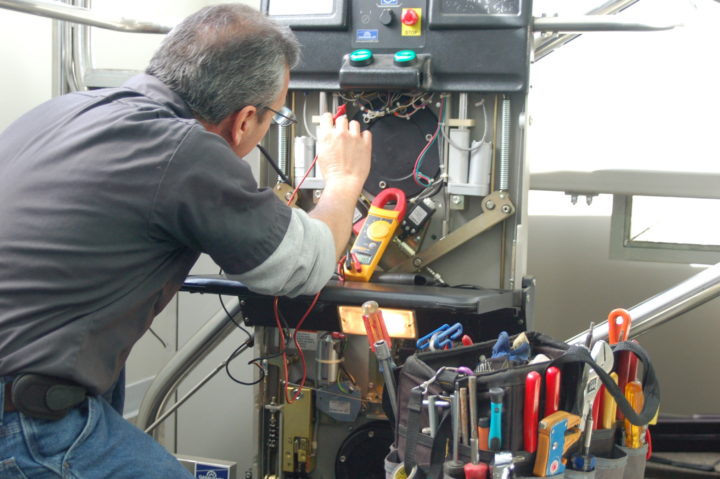

When it pertains to the risk-free and reliable procedure of lifts, taking into consideration essential upkeep variables is extremely important. Lifts are intricate systems that require thorough attention to information to operate reliably. From normal inspection schedules to sticking to appropriate lubrication methods, each element plays a critical duty in making certain the lift's long life and safety and security. Nevertheless, ignoring these maintenance methods can result in unexpected downtime, safety hazards, and pricey fixings. It is vital for developing managers and upkeep workers to stay in advance of these aspects to support the elevator's efficiency requirements and conformity demands.Regular Examination Schedules

Performing routine evaluations not only enhances the total efficiency of the elevator but additionally plays a critical role in following security regulations and sector requirements. It guarantees that the lift operates efficiently, reducing the risk of unexpected failures that might hassle occupants or concession safety. In addition, routine inspections add to lengthening the life expectancy of the lift devices, inevitably decreasing upkeep expenses and downtime.

To simplify the assessment procedure, numerous structure owners companion with certified elevator upkeep companies that focus on performing detailed assessments and supplying prompt maintenance solutions. By prioritizing normal assessment schedules, stakeholders can support the safety and security, reliability, and effectiveness of their lift systems.

Proper Lubrication Methods

Efficient lubrication techniques are important for preserving the optimum performance and durability of lift parts. Proper lubrication methods play a vital role in stopping damage on relocating components, reducing friction, and making certain smooth procedure of the lift system. When it involves elevator upkeep, utilizing the right lubricating substances in the proper amounts at the suggested intervals is key to decreasing and avoiding pricey repair services downtime.To make sure appropriate lubrication, lift service technicians should comply with producer guidelines regarding the type of lubricating substance to be made use of for details elements such as bearings, gears, and guide rails - lift maintenance london. Over-lubrication can draw in dust and debris, bring about part malfunctions, while under-lubrication can trigger enhanced rubbing and early wear. Frequently arranged lubrication maintenance need to be included in the overall elevator upkeep plan to keep the system running successfully and securely

Checking Tear and wear

Proper lubrication methods are indispensable in helping with the early detection and tracking of deterioration on lift elements. Normal lubrication assists decrease rubbing between relocating parts, preventing excessive wear and prospective break downs. Nonetheless, keeping track of damage exceeds just lubrication. Elevator upkeep employees ought to conduct routine inspections to recognize indications of wear on vital elements such as ropes, sheaves, overview rails, and bearings. These evaluations might include aesthetic checks, determining wear limitations, and making use of diagnostic tools to examine the problem of crucial parts. In addition, keeping thorough maintenance records can assist in tracking the wear patterns of elevator parts gradually, enabling predictive maintenance preparation. By very closely keeping an eye on wear and tear, upkeep teams can address concerns proactively prior to they rise right into costly repair work or unanticipated downtime, making certain the efficient and secure procedure of the lift system.

Safety And Security Compliance Checks

Performing comprehensive security conformity checks is crucial in guaranteeing the elevator system meets all governing standards and functional requirements. Safety compliance checks entail a thorough evaluation of various components such as emergency situation brakes, door sensing units, interlocks, and electric systems to ensure they are operating correctly. Normal examinations by certified specialists assist recognize prospective safety and security threats before they intensify right into significant problems, ensuring the safety of guests and conformity with sector policies. These checks additionally include verifying that the lift's capacity limitations, rate, and emergency communication systems are in line with safety and security requirements. Additionally, adherence to lift maintenance services security conformity checks can protect against crashes, reduce liability dangers for building owners, and prolong the lifespan of the elevator system. By prioritizing security conformity checks as part of regular upkeep, structure managers can promote a safe and reliable vertical transportation system for occupants.

Emergency Situation Feedback Planning

In light of the critical relevance of safety conformity sign in keeping elevator systems, a durable emergency action planning approach is critical to swiftly and properly address unforeseen incidents. lift maintenance company. Emergency action preparation for lifts entails positive measures to ensure the safety of travelers and upkeep personnel in case of emergencies such as power blackouts, entrapments, or mechanical failuresKey components of a reliable emergency situation action plan include establishing clear communication procedures, supplying normal training to personnel on emergency treatments, preserving updated emergency call checklists, and conducting regular drills to practice reaction activities. In addition, it is necessary to have actually marked workers in charge of working with emergency situation reactions and making sure that essential devices, such as emergency situation illumination and interaction tools, are in functioning order.

Verdict

Finally, it is crucial to prioritize routine evaluation routines, correct lubrication methods, keeping track of damage, safety compliance checks, and emergency situation action planning for elevator maintenance. By implementing these necessary factors, building proprietors can guarantee the safety and performance of their elevators, ultimately lowering the risk of mishaps and malfunctions. Constant upkeep methods are necessary for lengthening the life expectancy of elevators and making certain the wellness of individuals that count on them for transport.On a regular basis scheduled lubrication upkeep ought to be consisted of in the general elevator maintenance plan to maintain the system running effectively and safely.

Elevator upkeep employees need to perform regular assessments to identify signs of wear on essential parts such as ropes, sheaves, overview rails, and bearings. In addition, maintaining thorough upkeep documents can aid in tracking the wear patterns of elevator components over time, permitting for anticipating upkeep preparation. By very closely checking wear and tear, maintenance groups can deal with concerns proactively before they intensify right into costly repairs or unforeseen downtime, making sure the reliable and risk-free operation of the elevator system.

Report this wiki page